The essential roadmap for getting started with fast prototyping

Wiki Article

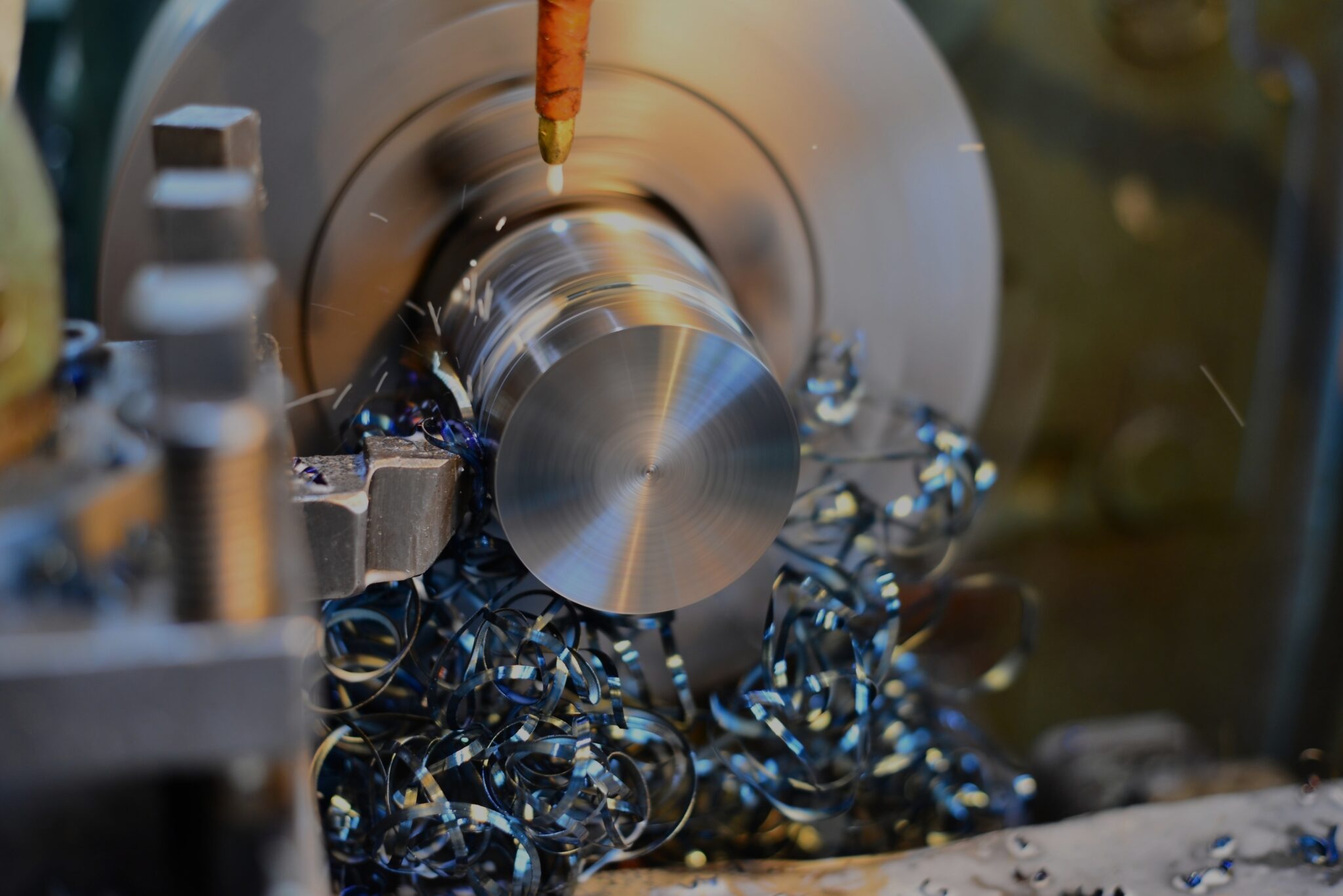

Discover the Benefits of Utilizing CNC Machining Providers for Accuracy Engineering and Manufacturing

CNC machining solutions provide considerable advantages for accuracy engineering and production. By employing sophisticated computer-controlled equipment, these solutions ensure high degrees of precision and efficiency. This modern technology enables the production of complex parts from different products, lowering human error and production time. Nonetheless, the benefits expand past precision alone, meaning deeper effect on productivity and cost-efficiency that are vital for modern-day sectors. Checking out these elements reveals a more substantial understanding of CNC machining's function.Boosted Precision and Accuracy

As industries progressively require higher requirements, CNC machining services have become a vital option for accomplishing enhanced precision and accuracy in engineering applications. These services utilize advanced computer-controlled machinery to produce detailed components that fulfill rigorous requirements. The capability to program exact measurements reduces human mistake, making certain that each component is produced to exacting tolerances.CNC machining is especially beneficial in markets such as aerospace, vehicle, and clinical devices, where precision is extremely important. The modern technology enables the development of complex geometries that typical machining approaches may struggle to achieve. By employing CAD versions, CNC devices can replicate styles with remarkable fidelity, resulting in regular quality throughout production runs.

Increased Effectiveness and Productivity

CNC technology enables for the synchronised handling of several parts, leading to greater manufacturing prices. The capacity to run machines constantly, even during non-working hours, optimizes functional time and resource usage. In addition, the fast setup and transition times linked with CNC machining promote quick adaptation to various project needs, allowing producers to respond promptly to market needs.

Affordable Manufacturing Solutions

Additionally, CNC machining enables rapid prototyping and manufacturing runs, which aids to enhance the production procedure and decrease lead times. The capability to produce intricate geometries with minimal material waste even more contributes to set you back financial savings. jig and fixture tooling. As a result, firms can allot funds extra efficiently and buy other locations of their procedures. Generally, CNC machining solutions provide a trusted path for services to improve productivity while keeping high criteria in product quality and efficiency

Versatility in Product Compatibility

The convenience of CNC machining services in material compatibility is just one of its most considerable benefits. This capability allows manufacturers to function with a varied variety of materials, including composites, steels, and plastics. Each material can be finely machined to meet details engineering needs, resulting in components that are both top quality and functional. For circumstances, steel and light weight aluminum are commonly utilized for their toughness and sturdiness, while plastics can be chosen for their light-weight and corrosion-resistant residential or commercial properties. CNC makers are equipped to deal with various material properties, making sure that the preferred specifications are met accuracy. This flexibility not just improves the style possibilities yet likewise allows producers to customize their products to various industry needs, from aerospace to clinical and auto applications. Inevitably, the ability to properly utilize several products enhances the manufacturing procedure and expands the range of ingenious engineering services.Structured Prototyping and Style Model

Simplifying the prototyping and style model procedure is an important benefit of advanced machining technologies. CNC machining solutions allow designers and designers to swiftly produce accurate prototypes, facilitating fast testing and examination. This performance significantly reduces the time from principle to production, making it possible for business to repeat styles promptly based upon real-world responses.CNC machining's high accuracy lessens mistakes, making certain that each model very closely mirrors the final product requirements. The ability to deal with numerous products even more enhances the design possibilities, enabling comprehensive testing throughout various situations.

Therefore, businesses can fine-tune their items better, adjusting to market demands and customer choices. This responsiveness is necessary in today's competitive landscape, where technology and speed are vital. Utilizing CNC machining solutions not only accelerates the advancement procedure but also enhances the general top quality and reliability of the final made goods.

Regularly Asked Concerns

What Industries Advantage A Lot Of From CNC Machining Solutions?

The aerospace, auto, medical, and electronic devices sectors benefit most from CNC machining solutions. These industries need high accuracy, complicated designs, and consistent top quality, making CNC machining necessary for producing complex components and conference strict sector criteria.Exactly How Does CNC Machining Contrast to Standard Production Methods?

CNC machining uses greater performance, flexibility, and precision compared to standard manufacturing techniques. It decreases human mistake, enables complex styles, and enables for quick prototyping, eventually causing improved production quality and reduced lead times.What Kinds Of CNC Machines Are Typically Used?

What Is the Normal Preparation for CNC Machining Projects?

The common preparation for CNC machining jobs typically varies from a few days to a number of weeks, depending on aspects like complexity, product availability, project dimension, and the manufacturer's workload, impacting general delivery timelines.Exist Any Type Of Limitations to CNC Machining Solutions?

CNC machining solutions do have constraints, consisting of product constraints, complexity of designs, cnc turning service and dimension limitations. Furthermore, detailed geometries may require customized tooling, which can increase production time and expenses, impacting general project expediency.CNC machining solutions supply substantial benefits for precision engineering and manufacturing - cnc milling services near me. As industries increasingly demand higher requirements, CNC machining solutions have arised as a necessary remedy for achieving improved precision and precision in engineering applications. CNC machining services not just improve accuracy but also substantially boost efficiency and productivity in producing processes. CNC machining supplies higher accuracy, adaptability, and efficiency compared to typical production approaches. Generally made use of CNC equipments consist of CNC turrets, CNC milling machines, CNC routers, CNC plasma cutters, and CNC laser cutters

Report this wiki page